Western Canada’s Leading

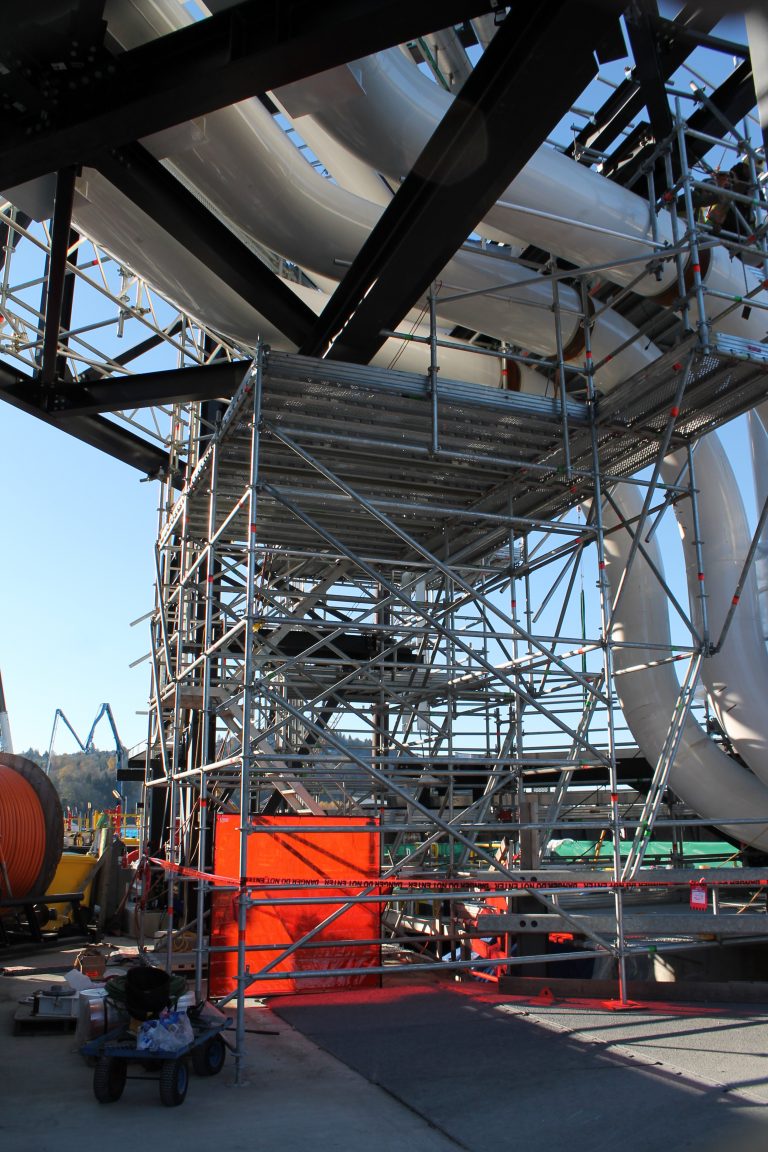

WESTCAN’s scaffolding engineers come from a wide range of professional backgrounds. From the simplest scaffold to the most complex, we’re here to help our clients find solutions and make sure they’re delivered on time. With solutions-focused, exceptional scaffolding design engineering for complex projects, WESTCAN Scaffolding is the leader in Western Canada.

for the type of scaffolding work they are performing and to have received adequate scaffolding training based on the type and complexity of scaffolding they are working with.

It is the employer’s responsibility to provide scaffolders with appropriate levels of supervision based on the complexity of the work and their training and competence levels.

Regardless of the type or complexity of the scaffold to be erected, altered, or dismantled, every scaffold gang must include a competent scaffolder.

It is mandatory for trainee scaffolders to work under the supervision of a competent and trained scaffolder. As trainees, operators are not deemed competent until they have completed the approved training and assessment requirements.

Every scaffolding structure (basic or complex) should be erected, altered, and dismantled under the supervision of a competent individual. Complex structures usually require an ‘Advanced Scaffolder’ or an individual with training in a specific type of scaffold, depending on the configuration involved.

Occupational safety guidelines and good working practices within the scaffolding industry should be kept up-to-date by scaffolding operatives. Keep operatives informed by providing them with pre-start briefings and regular toolbox talks.

Scaffolding inspections must be performed by a competent individual with the necessary knowledge, training, and experience. The competence may have been assessed under WorkSafeBC or the individual may have been trained by a manufacturer/supplier to inspect a specific type of system scaffold.

In some cases, a non-scaffolder, such as a site manager, may be able to inspect a basic scaffold structure after attending a scaffold inspection course.

Regardless of whether corrective measures are taken right away, the report should note any defects or matters that could pose a risk to health and safety, as this assists in identifying any recurring problems.